Product Description

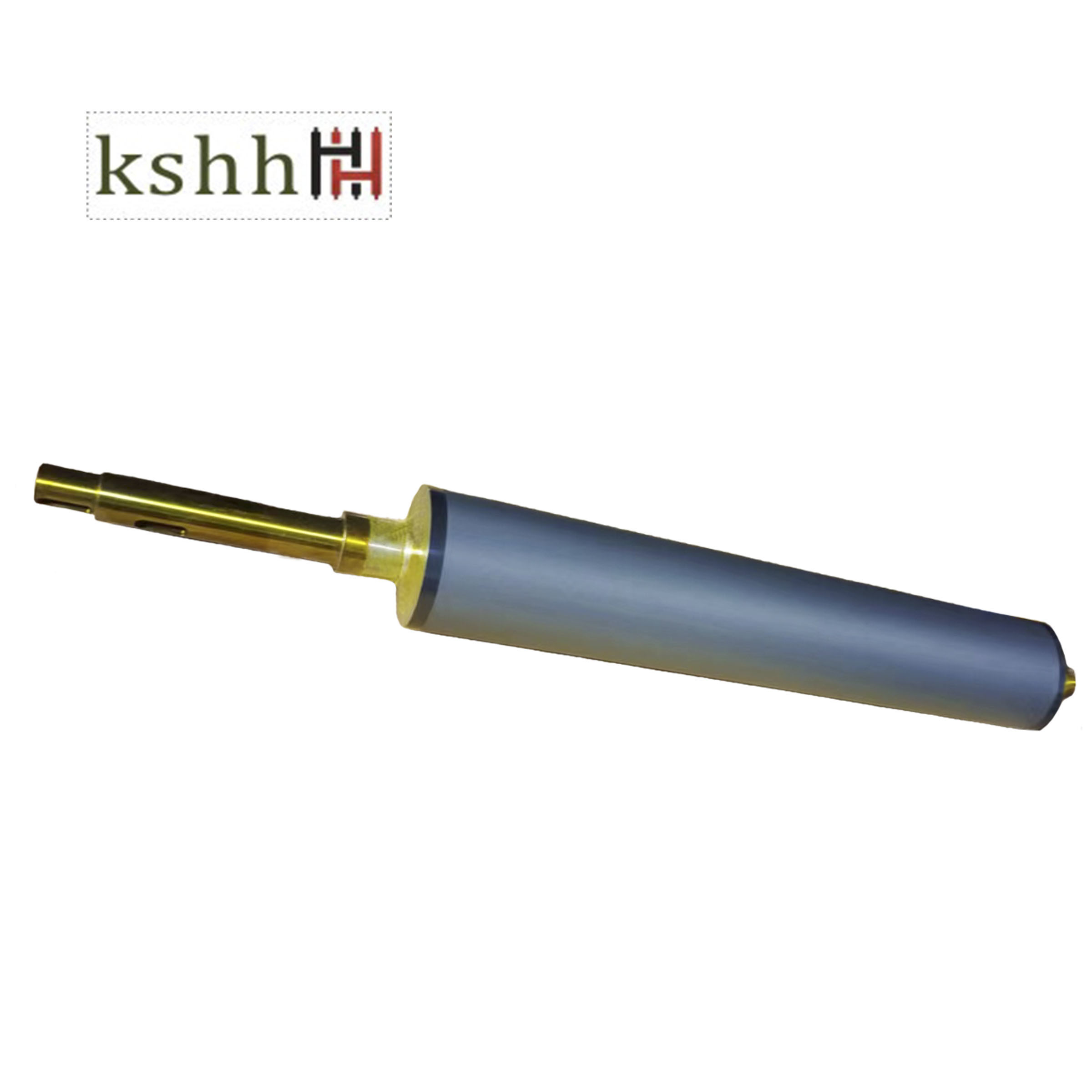

Ceramic Anilox roller:Description:

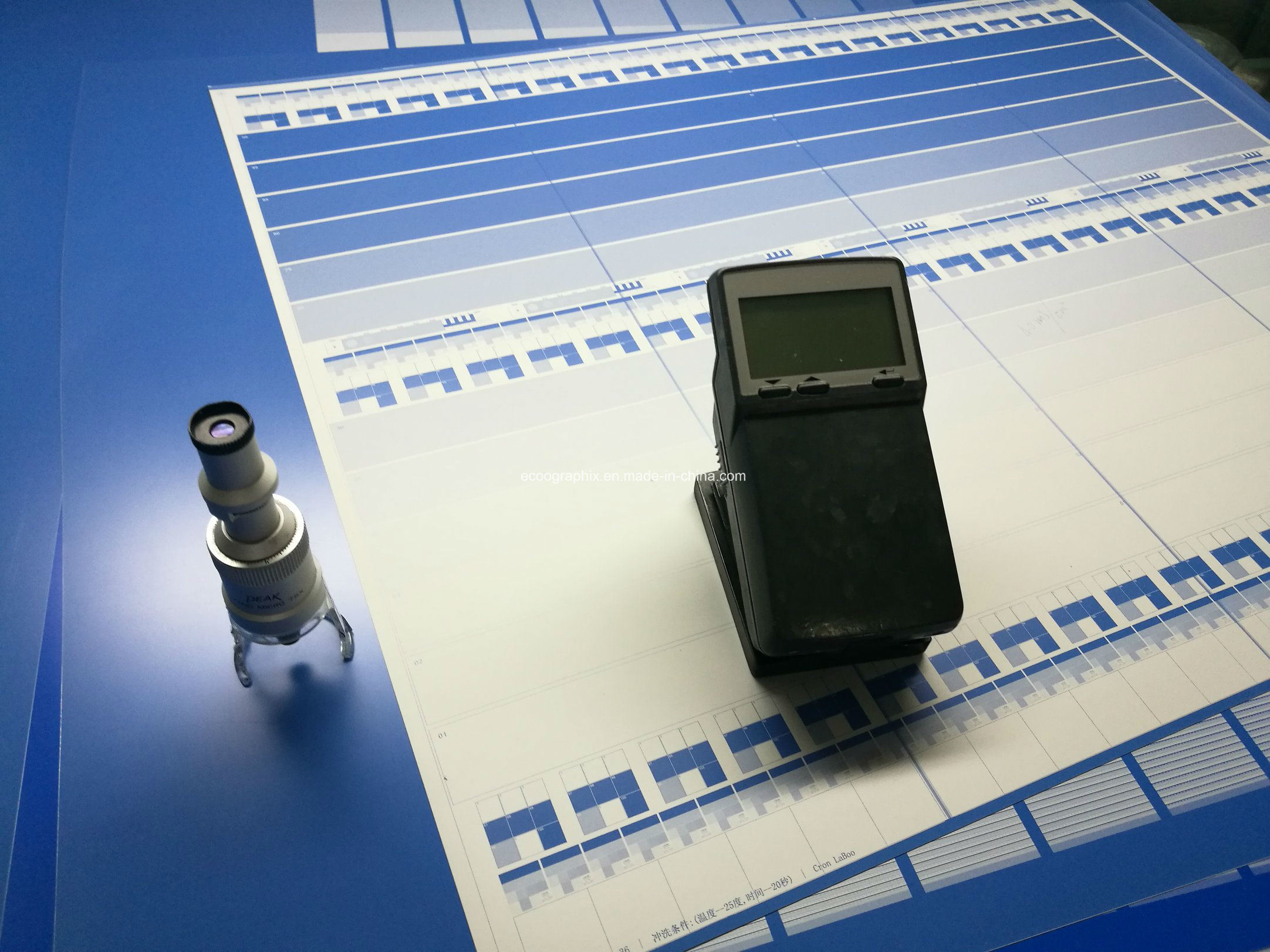

A common method used during the printing and coating process is anilox- it's a way of measured amount. The base material of anilox rolls are the hard steel or aluminum cylinders, nowdays carbon fiber or glass fiber tube is also used widely for anilox sleeve. The surface of face roller are coated by an industrial ceramic. And then it's laser engraved with very tiny dips, forming anilox cells. The engraving pattern used will affect the anilox efficiency, and therefore it is very important to choose the correct pattern and cell shape that will provide the best results. During printing, the anilox rolls are coated in a measured amount of ink that is then rolled over the raised portion of the flexo printing plate.

Application:

Main used in printing, coating, laminating, varnishing etc.

Advantage:

Wear resistance;

Corrosion resistance;

High-temperature resistance;

With stable and wide regulating range of ink transfer;

Easy to clean; Long life time to use.

Processing Machines:

Engraving machine:

Ceramic Coating Machine:

Specifications:

Diameter 40 - 600 mm,

Length 5500 mm

Runout: 0.01mm

Screen: 50-1600 LPI

Cell shape: Quad, Hexagon, Tri-helical etc

Printing Way:

| Diameter: | 40-600mm |

| Length: | 5500mm |

| TIR: | 0.01mm or less |

| Screen: | 60-1400LPI |

| Cell shape: | Quad, Hexagon, Tri-helical etc |

| Payment: | T/T |

| Delivery time: | 15-18days |

| Price: | according to customer' s drawing(detail spec) |